Sauce dispenser pumps are fundamental devices in the meal industry, guaranteeing productive and controlled dishing out of sauces, fixings, and dressings. However, without legitimate upkeep, these pumps can become favorable places for microscopic organisms and toxins. Regular cleaning is vital now, not only for hygiene but also for prolonging the life of the device and maintaining the exceptional quality of your products. Before diving into the cleaning process, it’s vital to understand the fundamental additives of a sauce dispenser pump.

Gather the important tools and substances before starting the cleansing procedure. Consistent cleaning practices reflect undoubtedly the popularity of the food establishment. Customers are much more likely to consider and patronize institutions that prioritize cleanliness and hygiene standards, mainly to expand pleasure and loyalty. In essence, cleansing sauce dispenser pump aren’t always just about assembly regulatory necessities; they are about ensuring the fitness, delight, and consideration of clients, as well as preserving the integrity of the enterprise.

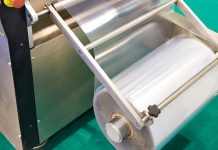

Step-By-Step Process For Cleaning Sauce Dispenser Pumps

In this article, we will delve into the quality practices for cleansing sauce dispenser pumps, specializing in simplicity and effectiveness.

Disassembly

Disassembling the sauce dispenser pump is the initial step in the cleaning process. Cautiously follow the producer’s instructions to get rid of the pump mechanism, tubes, and any removable additives. Be aware of the arrangement of the components for easy reassembly later. This step sets the level for thorough cleansing and ensures that every additive is nicely sanitized before reassembling the pump.

Pre-Rinse

After disassembly, rinse all components under warm running water to dispose of visible sauce residue and particles. Utilize a brush or sponge to softly scrub any stubborn buildup, paying close attention to crevices and hard-to-attain areas. This pre-wash step permits surface impurities to be slackened, making the resulting cleaning more compelling. Completely washing the parts guarantees that no extra buildup compromises the neatness of the pumps for the duration of the cleaning system.

Cleaning Solution

Put together a cleaning solution by combining heated water with a mild dish cleaning soap. Submerge all disassembled pump components inside the solution, making sure they’re immersed. Permit the components to soak for several minutes to loosen any closing residue and grease. This answer correctly breaks down stubborn buildup, facilitating less complicated scrubbing in the subsequent steps. Well, getting ready for the cleaning answer is crucial for attaining thorough cleansing effects.

Scrubbing

Use a cleaning brush or sponge, to scrub each pump component very well to get rid of any final residue. Pay unique attention to areas liable to buildup, inclusive of the pump mechanism and valves. Appoint mild but firm scrubbing motions to ensure powerful cleansing without adversely affecting the surfaces. This step eliminates cussed contaminants, getting ready the additives for rinsing and sanitization inside the subsequent levels of the cleaning technique.

Rinse And Sanitize

When all pump parts are thoroughly cleaned, wash them very well under hot running water to eliminate any cleanser buildup. Then, keep on cleaning the parts by either submerging them in a disinfecting solution or cleaning them with a texture-absorbed sanitizer. Observe the manufacturer’s suggestions for proper attention and speak on time to ensure effective disinfection. Proper rinsing and sanitizing are essential for getting rid of microorganisms and ensuring meal protection.

Drying

After sanitizing, allow the pump components to air dry completely in an easily ventilated place. As an alternative, use clean towels or paper towels to pat them dry very well. Make certain that no moisture remains on the surfaces, as dampness can promote bacterial growth. Right drying is important for stopping contamination and retaining the cleanliness of the pump components before reassembly and subsequent use in food service operations.

Reassembly

Cautiously reassemble the pump additives, ensuring that each part suits collectively efficiently in step with the producer’s commands. Seek advice from any notes or photographs taken during disassembly to find useful resources inside the reassembly method. Take care to align seals and valves properly to prevent leaks or malfunctions. As soon as it is reassembled, take a final look to make sure that the pump operates easily and dispenses sauce successfully before returning it to the carrier.

Remarks

Right cleansing and renovation are vital for ensuring the protection and performance of sauce dispenser pumps. With the aid of following the step-by-step cleansing process outlined in this guide and implementing regular renovation practices, you could keep your gadget in top condition while at the same time upholding the very best hygiene requirements for your meals’ established order. A clean pump isn’t always only a testament to your dedication to first-class service but also a crucial step in safeguarding the fitness of your customers.