Exploring the Differences and Applications of Sinker EDM vs Wire EDM

Embarking on the world of machining marvels with 3ERP introduces us to two extraordinary techniques: Sinker Electrical Discharge Machining (EDM) and Wire EDM. Imagine them as superheroes in the machining universe, each with its unique set of powers. Sinker EDM, our crafty sculptor, uses sparks and a magic liquid potion to shape intricate designs.

While Wire EDM, the nimble dancer, elegantly cuts through materials with a continuous wire. In this exploration, we’ll unravel the main differences and discover the specific applications that make Sinker EDM vs wire EDM the dynamic duo in 3ERP’s machining arsenal. Get ready to dive into the world where precision meets craftsmanship!

Differences and applications of Sinker EDM and Wire EDM

In the world of precision machining, two popular techniques stand out: Sinker Electrical Discharge Machining (EDM) and Wire EDM. While both methods fall under the EDM umbrella, they have distinct differences in their processes and applications. Now we’ll delve into the basics of Sinker EDM and Wire EDM in simple terms, highlighting their main differences and exploring where each shines in various applications.

Sinker EDM

Sinker EDM, also known as Ram or Die-Sinking EDM, involves creating intricate shapes by using an electrode (often made of graphite or copper) to erode the material. This is achieved through a series of controlled sparks between the electrode and the workpiece submerged in dielectric fluid. The sparks remove material, leaving behind the desired form. Sinker EDM is ideal for producing complex and detailed molds, dies, and prototypes with high precision.

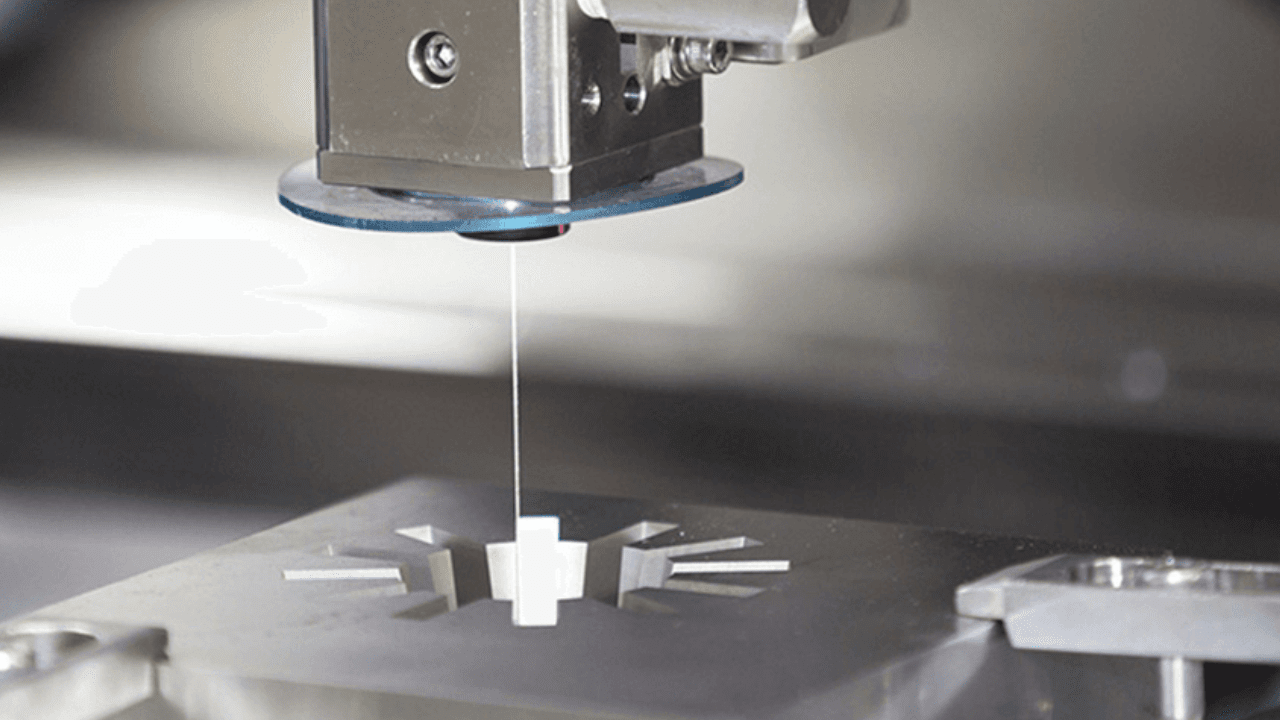

Wire EDM

Wire Electrical Discharge Machining (Wire EDM) is a precision technique that showcases the cutting-edge capabilities of modern machining. In this process, a thin wire, often made of brass, is used as a cutting tool. This wire, guided by a computer program, moves in a controlled manner to slice through the workpiece with exceptional accuracy.

Wire EDM is like a skilled dancer on the machining stage, gracefully executing intricate movements to create precise and detailed components. Wire EDM is deployed in various applications where high precision is paramount, such as crafting aerospace components, manufacturing delicate medical devices, and producing tool and die creations with razor-sharp accuracy.

Main Differences

Sinker EDM and Wire EDM are two superheroes in 3ERP’s machining universe, each with its unique powers. Sinker EDM, like a skilled sculptor, uses a special electrode to shape intricate designs with sparks in a liquid magic potion. It excels at crafting molds, dies, and prototypes, bringing three-dimensional dreams to life. On the other hand, Wire EDM is the nimble dancer, utilizing a continuous wire to elegantly cut through materials with precision.

Its finesse shines in creating aerospace components, delicate medical devices, and razor-sharp tool and die creations. The main difference? Sinker EDM sculpts with sparks, while Wire EDM gracefully slices with its continuous wire, both ensuring that 3ERP’s machining capabilities meet the highest standards of precision and craftsmanship.

Applications

Sinker EDM and Wire EDM, the dynamic duo at 3ERP, have unique applications that make them shine. Sinker EDM, our crafty sculptor, is the go-to for crafting molds for plastic injection, producing dies for metal stamping, and breathing life into intricate prototypes. Its versatility allows it to navigate the complex world of three-dimensional shapes with precision and detail.

Meanwhile, Wire EDM, our nimble dancer, takes the spotlight for precision-centric applications. It crafts aerospace components with intricate details, manufactures delicate medical devices, and produces tool and die creations with razor-sharp accuracy. Together, these machining superheroes ensure that 3ERP brings your ideas to life with a perfect blend of precision and craftsmanship, tailored to the specific needs of each application.

Conclusion

In simple terms, while both Sinker EDM and Wire EDM fall under the EDM category, their methods and applications vary. Sinker EDM is your go-to for detailed molds and dies, while Wire EDM shines in applications demanding high precision and intricate shapes. Understanding these differences helps manufacturers choose the right EDM technique for their specific needs, ensuring efficient and precise machining in various industries.